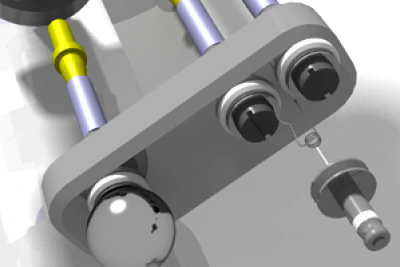

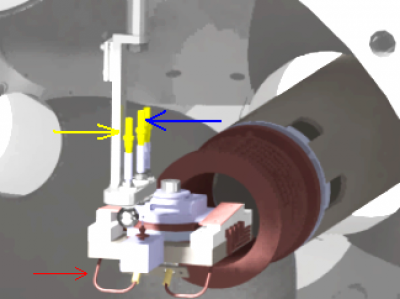

preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC, preparation, stage, filament, emission, current, preparation station, hsasm tipebfe, spherical electrode, field emission, arrow last, last picture, picture below, arrow last picture, last picture below, HSASM40-TIPEBFE2-MD16(TS)-ESFC